Ultrasonic spray coating is a process that uses high-frequency sound waves to apply a thin, continuous film of coating to an object. It’s used in a wide variety of industries, including automotive, medical, and consumer products. Ultrasonic spray coating can be used to create smooth or textured finishes on objects and has many benefits, including:

- quick and easy application

- high precision and accuracy

- low waste rate

- ability to cover large areas quickly

- low cost of operation

- a versatile and cost-effective process that can be used for a variety of applications.

What is Ultrasonic Spray Coating?

Ultrasonic spray coating is a heat treatment process that uses ultrasound waves to apply a uniform coating of paint, varnish, or other material to a surface. The ultrasonic waves cause the material to vibrate and create tiny bubbles that carry the coating to the surface. This process is faster and more accurate than traditional methods, and it can be used to coat delicate surfaces like glass.

Ultrasonic spray coating is a versatile and cost-effective process that can be used for a variety of applications. It’s fast and easy to apply, and it has high precision and accuracy. Plus, it has a low waste rate and can cover large areas quickly.

Advantages of Ultrasonic Spray Coating

Ultrasonic spray coating is a type of coating that uses ultrasonic energy to atomize the coating material and create a thin film on the surface. The ultrasonic energy breaks down the molecules in the coating material, creating a gas and liquid mixture that is then atomized and directed to the surface.

The main advantages of ultrasonic spray coating are its ability to create a very thin film with minimal waste and its ability to uniformity coat large areas quickly. It is also less expensive than other types of coatings, making it an attractive option for small businesses that do not have the resources to invest in more complex coatings techniques.

Disadvantages of Ultrasonic Spray Coating

Ultrasonic spray coating is a process that uses high-frequency sound waves to atomize the liquid coating material and create a thin film on the surface. The advantage of ultrasonic spray coating is that it can be done quickly and at a low cost, which makes it an attractive choice for small to medium-sized batches. However, there are some disadvantages to consider when using ultrasonic spray coating.

First, ultrasonic spray coating can create microscopic bubbles in the liquid coating material, which can cause defects in the film formed. Additionally, ultrasonic energy can damage the paint and other substrates, so it’s important to use proper safety precautions when using this technology. It does not protect the surface from moisture or corrosion.

Another disadvantage of ultrasonic spray coating is that the film formed by the process may be less durable than films formed using other coating technologies. It is less effective at creating a smooth, consistent finish than other methods, so it may not be suitable for applications where a high degree of precision is required.

How Does Ultrasonic Spray Coating Work?

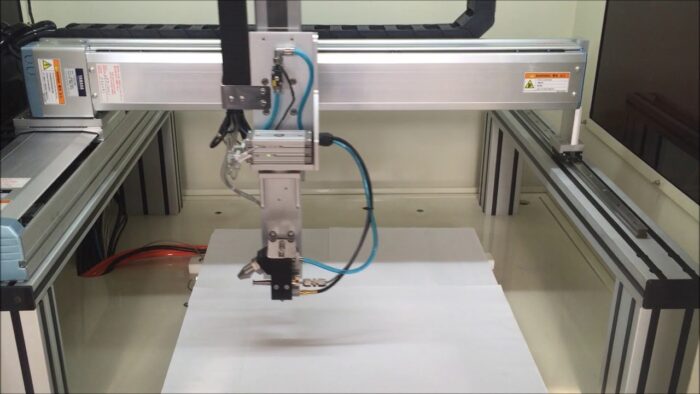

Ultrasonic spray coating is a new type of coating technology that uses high-frequency sound waves to create a thin layer of material on the surface of objects. The high-frequency sound waves cause the liquid coating to vibrate and oscillate, creating a continuous film of liquid on the object’s surface. The ultrasonic spray coating process is fast and efficient, and it can be used to coat a variety of materials, including metals, plastics, and composites.

This type of coating has many advantages over other coating technologies. First, it is fast and easy to use, so it can be used for small batches or quick turnaround times. Second, it is non-toxic and environmentally friendly, so it can be used on a wide range of objects. Finally, ultrasonic spray coating produces a very strong finish that can resist scratches and other damage.

Safety Measures

Safety measures are necessary when working with any type of chemical. Ultrasonic Spray Coating is one of the safest methods for coating surfaces and it is an effective method for providing a barrier to prevent the chemical from entering into contact with skin or eyes.

This technology utilizes sound waves to coat surfaces without using solvents or dust particles, which can cause safety concerns like respiratory issues and skin irritation.

There are a few safety precautions that should be followed when using ultrasonic spray coating:

- Always wear protective clothing and eye protection.

- Use the lowest possible setting when spraying.

- Do not overapply the coating.

- Remove the coating after it has dried.

The most important safety precaution is to follow the manufacturer’s instructions and use the lowest possible setting when spraying. If the coating is accidentally applied too thickly, it may not be effective and should be removed. When using ultrasonic spray coating, it is important to keep the area clean and dry. Any excess coating should be removed after it has dried.

You should always consult a professional to do your toll coater.

How Ultrasonic Nozzles Work

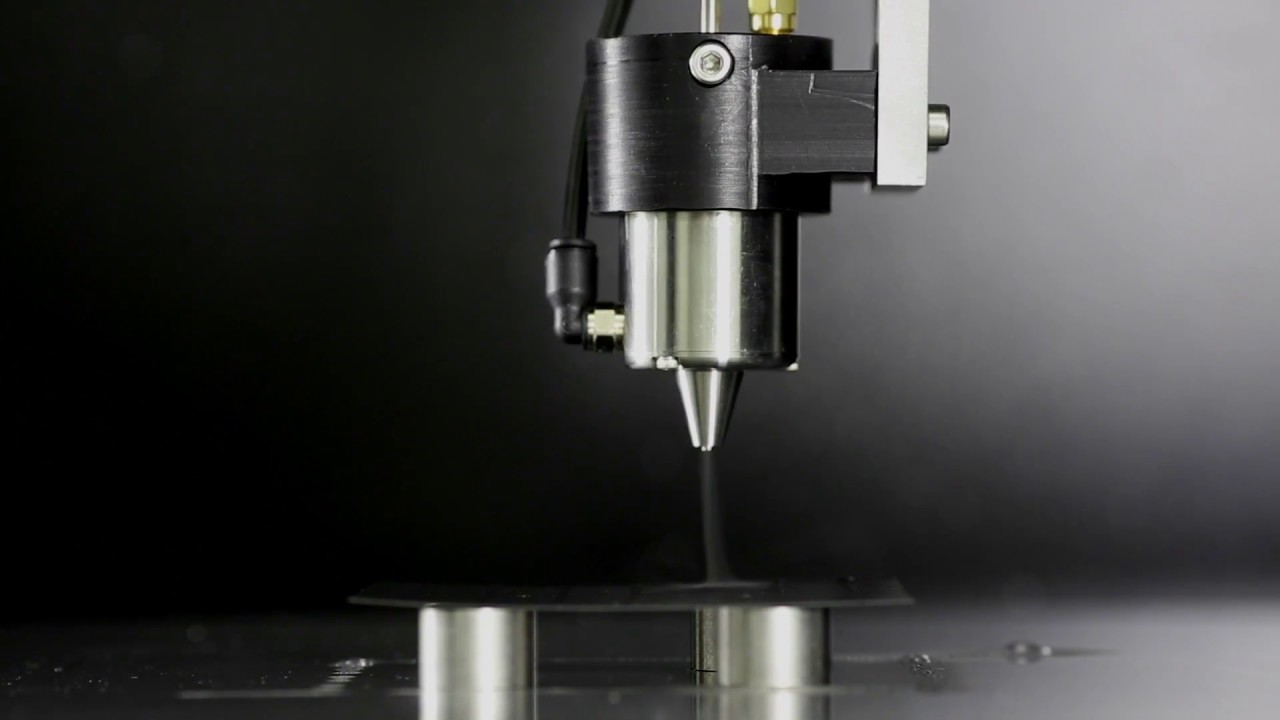

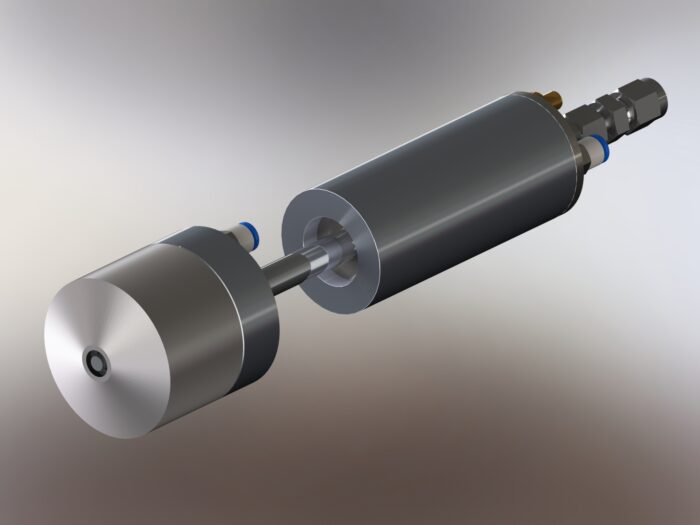

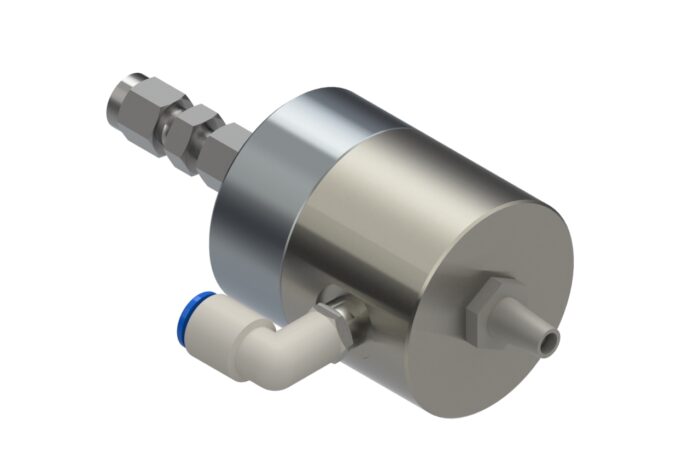

Ultrasonic nozzles operate by vibrating the liquid in a container at ultrasonic frequencies (greater than 20 kHz). This vibration causes the molecules in the liquid to break apart into smaller particles which then mix with air creating a mist of droplets that is atomized into a fine, high-velocity spray.

They were first developed in the 1950s and are now used in various industries such as automotive, aerospace, electronics, and industrial applications. They are also becoming more common in the construction industry due to their ability to apply coatings at a faster rate than traditional methods.

Conclusion

Ultrasonic spray coating is an environmentally friendly process that does not require any harsh chemicals or solvents, making it ideal for use in sensitive environments.

FAQ

1. How does an ultrasonic atomizer work?

An ultrasonic atomizer works by using an ultrasound wave to vaporize the liquid nicotine. The ultrasound waves cause the liquid nicotine to heat up and turn into a vapor.

2. How do you make an ultrasonic mist?

There is no definitive answer to this question as the method of making an ultrasonic mist will vary depending on the type of ultrasonic generator being used and the specific needs of the individual. However, some methods for making an ultrasonic mist include using a pump to create bubbles of air or water, using a generator to produce high-frequency sound waves, and using a microphone to capture and amplify sound waves.

3. What frequency do ultrasonic humidifiers use?

Most ultrasonic humidifiers use a frequency of around 20,000 hertz.