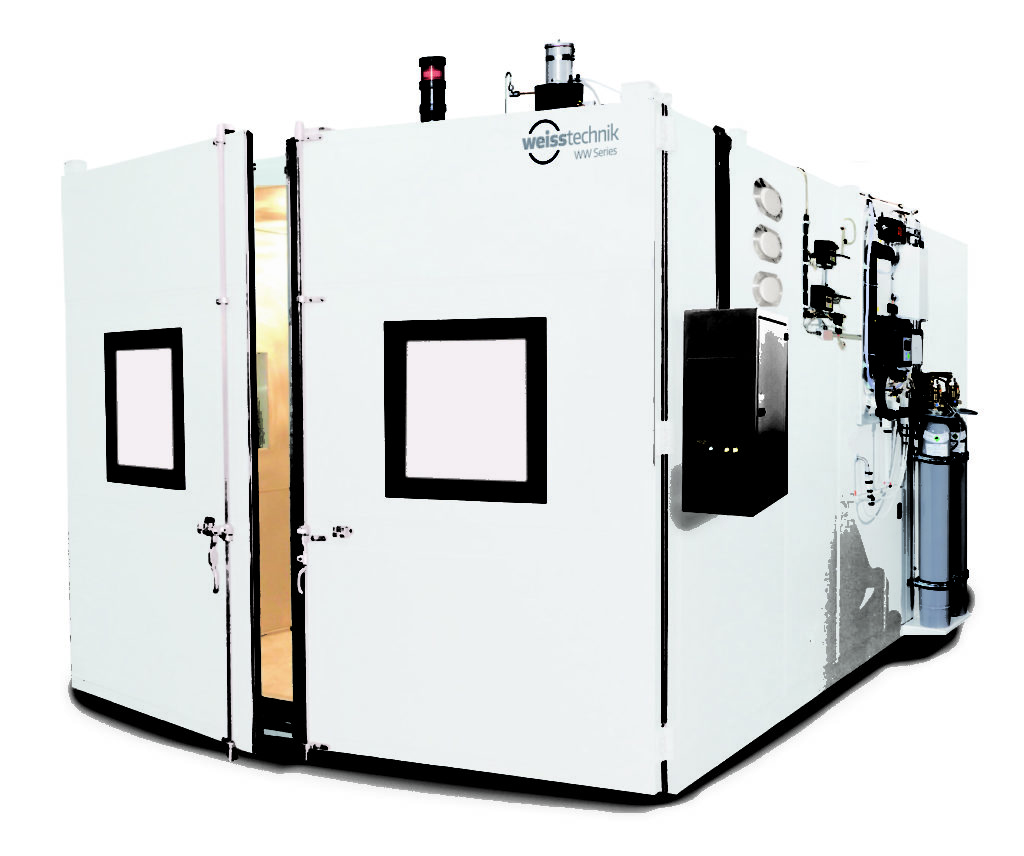

For years now, environmental test chambers have been used to test and study products in fields like artificial intelligence, automotive, electronics, aerospace, medical, industrial, solar cell, and consumer research. In these industries, the material or sample tested needs to be exposed to specific variations of environmental factors in order to study the effect or to prepare for future studies.

There are different conditions that the environmental test chambers replicate including temperature set-points, moisture in the form of rain or humidity, vibration, electromagnetic radiation, salt spraying, weathering, sunlight exposure, UV degradation, and vacuum. The type of testing determines the chamber type needed – since they come in a wide range of designs and sizes with different features, options, and functionality.

The prepared material, substance, or product is placed in the chamber and then it is subjected to specific levels of environmental stimuli in order to determine the degree to which the object reacts. Also, the resulting by-products are also studied and measured. If you want to see the more about these chambers, visit this website.

The Uses of Environmental Chambers

Environmental chambers can be used to test products from these industries: building materials, automotive, electronics, timber, chemicals, cosmetics, aerospace, plastics, metal, tobacco, pharmaceuticals, textile, biotechnology, bio-tissue engineering, packaging industry, ceramics, food and beverage, human and veterinary medicine, surface technology, microbiology, and plant and insect growth.

When it comes to food, cosmetics, and pharmaceutics, environmental and stability chamber monitoring is important in order to comply with the rules that are established by the international regulatory agencies. The chambers can measure and control temperature, humidity, particle counts, different pressure, gas level, lighting, and other things. Also, advanced aging research within the test chambers can help with determining a safe shelf-life and use-by dates.

In microbiology and biology, the chambers are used for monitoring the effects of humidity, light, and other factors on the growth of viruses, plants, algae, small animals, and insects. They enable the organs and tissues, the culture of cells, and plant growth, as well as insect rearing.

The aerospace industry relies on these chambers to make a vacuum, thermal experiments, and thermal vacuum that replicate the outer-space conditions, hence, the space system hardware can withstand the extreme conditions of climate and pressure.

In the automotive industry, the chambers are used to create conditions like hot roads, extreme exposure to sunlight, corrosion level, amongst other things. All car factories perform these test, most of which use drive-in chambers located in the companies’ testing facilities. They create real-life conditions such as wind speed, normal humidity level, air and road temperatures, and extreme conditions. Hence, the manufacturer can check the vehicle’s performance and durability.

Besides the complex research protocols used by large manufacturers, universities, research organizations, and quarantine bureaus, environmental chambers are also used for addressing the quality control inspection of every-day products like batteries, electrical appliances, paper products, food, and plastics.

Conclusion

As you can see, the importance of environmental test chambers is big since it plays a major role in developing and appraising performance and features of marketable products. They have a large role in advancing technology to higher levels while making sure that the products are reliable and safe for everyday use.