Retaining walls are crucial construction elements since they are installed to help withstand the constant pull of gravity and hold back soil mass. Hence, there are many factors that contractors need to look into before using them in industrial construction projects.

Seeking professional recommendations to thoroughly evaluate prevailing soil conditions at worksites is essential in determining whether retaining walls are a suitable support element in construction jobs.

When the work requires retaining walls to establish vertical separations between adjacent ground levels, a strategically installed retaining wall system must reinforce the higher ground. Uneven ground takes too much space and is nearly impossible to be considered helpful in any application.

The installation of vertical retaining walls addresses uneven slopes and steep inclines as they offer superior stability in the long run. Here are the most common advantages of utilizing retaining wall systems in the industrial construction setting.

Reinforcing soil slopes

The installation of vertical slopes facilitates the quick and efficient leveling of slopes, resulting in the expansion of functional spaces in industrial settings and mining construction initiatives. Additionally, retaining walls are the perfect structures to create high-level platforms.

Compared to traditional concrete walls, retaining wall systems provide superior stability thanks to their inherent construction and design features. To check out innovative and functional retaining wall design options, click here.

Cost-effective site reinforcement alternative

Apart from its reliability in leveling uneven soil and steep slopes, retaining walls offer other vital benefits. Unlike traditional reinforcement materials and construction techniques, installing retaining walls systems save time and money.

Since they arrive at worksites prefabricated, contractors only need to install them in place through their respective installation strategies. When properly installed, retaining walls become an essential structure that can support massive loads over time.

Simple and sleek aesthetic structures

Retaining walls are simple yet sleek construction features that come in various dimensions, sizes, and textures. Depending on the design aesthetic the contractors wish to display, retaining walls can be painted or decorated with greens or flowers. The simplicity of its design makes retaining wall systems double as an aesthetic fixture for interior and exterior industrial spaces.

Easy to transport

The modular design of retaining wall systems means they can be easily transported to worksites. Contractors save money on retaining walls as they do not require crane rentals and specialists to transport retaining walls safely from one site to another.

For industrial builders looking to cut costs, structural fill for retaining walls can be obtained from third-party suppliers and mine spoil. In some cases, recycled aggregate can also save money while ensuring stability and longevity. Lastly, retaining walls showcase a greater level of flexibility as they can be cut and fitted into any space, enabling contractors to complete projects without delay.

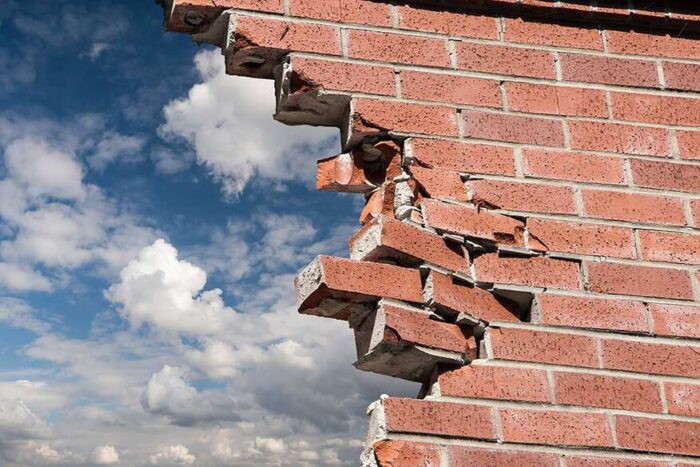

While retaining walls are unmatched for their superior strength and power in bearing loads, a few limiting conditions can lead to its failure. Therefore, contractors must create a strategic plan to avoid extrinsic factors that could impact the design and functionality of retaining wall systems negatively. Here are the most common issues that arise with improper retaining wall installation.

Overturning

Overturning occurs when the lateral weight and outside forces go beyond the total weight of retaining walls.

Sliding

The wall may slide down if the total lateral trust goes beyond the frictional resistance existing between the base portion of a retaining wall and the soil.

Bearing on the ground

The prevailing pressure that exists between the base of a retaining wall and the soil can result in bearing failure of the soil if the maximum bearing capacity is exceeded. Typically, the ideal bearing pressure is one-third of its maximum value. The pressure distribution differs from one site to another.

Rotational slip

A rotational slip occurs when a retaining wall and a large amount of soil, rock, and other retained materials rotate or move at some point.

Wall material failure

The retaining wall structure itself should have the inherent ability to bear internal stresses. Ideally, the stresses must not exceed typical values. To establish long-term safety, it is therefore essential to seek the recommendations of engineers and other construction experts to determine the allowable stress applied on specific retaining wall systems. The shear and bending elements of a retaining wall are factored with the tension failure and permissible stress of the front or anterior face.

Joint failure in block work

Gravity retaining walls are highly dependent on factors such as the overall impact of gravity, self-weight, and its stability features. Other types of walls depend on the durability and sturdiness of their base combined with a wall designed to withstand bending to develop a structure that remains firm and solid over time.

The pressure of granular materials

Granular materials, including gravelly soil, grain, and sandy soil, possess internal friction properties. If granular materials are set in a dry condition and set on a flat surface, they form a conical heap reinforced by the internal friction between grains. Disturbance or instability in the granular structure can result in poor internal friction. This condition can dramatically reduce the stability of the retaining walls altogether.

Retaining walls are the most common structures used in constructing mining features, reinforcing bridge abutment and any industrial setting that suffers from uneven or poor soil conditions. They are unmatched in strength and durability; hence, retaining walls are preferred in establishing high walls.

Conclusion

The overall performance and quality of retaining wall systems are integral in various stages of construction as they guarantee long-term durability and safety. Additionally, retaining wall systems are instrumental in establishing dependable reinforcement in the long run.

When looking for a manufacturer to purchase retaining walls from, builders must narrow their list to companies with a sterling track record in fabricating durable and long-lasting retaining walls that have passed strict quality control.

A company prioritizing excellence over profits implements various testing protocols and best practices to establish superior structural integrity of its retaining wall systems. Finally, a reputable manufacturer also ensures ongoing support should clients require additional aid and design recommendations during the installation phase.