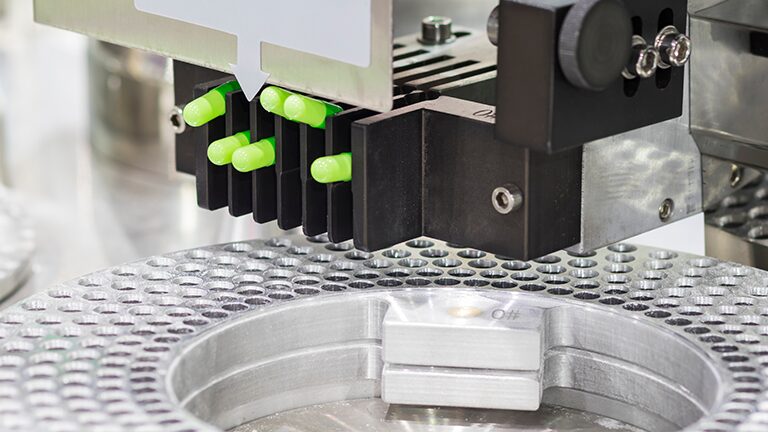

No pharmaceutical company is complete without the production of capsule medicines. And naturally, capsules can only be filled with medicines with a capsule-filling machine. These machines fill various substances into smaller capsules, including vitamins, minerals, oils, and medicines.

Moreover, a liquid capsule-filling machine is not restricted to the pharmaceutical or medicinal drugs industry. They have been efficiently implemented in the cosmetic, personal care, and food and beverage industries along with their most prominent investors, the medicine manufacturing companies. In this era, most of these industries would be unable to function without this machine.

Different Industries Where Liquid Capsule Filling Machines Are Extensively Used

The invention of the liquid capsule-filling machine has been introduced previously. However, as the technology developed further, with minor alterations and modifications to the existing mechanism, numerous other industries also adopted the machinery. Since then, capsule-filling machines have proven extraordinarily versatile and efficient in every industry.

Here is how this machine is used and implemented in various industries:

The Pharmaceutical And Medicine Manufacturing Industry

Whenever we think about capsules, the very first thing that comes to any individual’s mind is medicine. The biggest and most significant user of capsule-filling machines is the pharmaceutical industry. A considerable bulk of capsules are filled with liquid medicines with the help of this machine daily.

Antibiotics, cough syrups, and pain relievers are often sold in capsules. This machine is used to precisely and carefully fill those capsules. They are primarily automatic and do not need any manual effort to work.

Liquid-filled capsules are especially beneficial for patients and children with difficulty swallowing significant medicines and pills. These capsules get easily dissolved and quickly absorbed by the body.

The Nutraceutical Manufacturing Companies

In addition, liquid capsule filling machines are employed in manufacturing nutraceuticals, which are nutritional supplements offering health advantages above and above essential nutrition. These supplements frequently include liquid components that may be enclosed in capsules utilizing liquid capsule filling equipment, such as fish oil or herbal extracts.

The concern about personal health has become crucial in the current generation. Nearly every person works a lot and thinks about remaining in the pink of health. Due to this, the sales and popularity of dietary supplements available in capsules have significantly risen. As the amount of liquid-filled capsules increases, it would automatically increase the number of liquid capsule-filling machines being used!

Cosmetic And Personal Care Manufacturing

The liquid capsule-filling machine has continued in the pharmaceutical and nutraceutical industries. It is used profoundly in cosmetic and personal care manufacturing factories to fill capsules with cosmetic solutions and skin care liquids. These capsules must be filled with precision which is difficult if done manually.

How do you think the currently trending vitamin E capsules are filled? It is none other than the highly effective liquid capsule filling machines. These machines fill essential oils, serums, and other skincare products in cosmetic manufacturing companies. These liquids are not supposed to be touched by human hands to prevent any foreign particles from entering the product solution. This is also another reason why automatic machines are utilized for the job.

Food And Beverage Manufacturing Factories

Did you know several flavoring agents are available in capsules? This is how the capsule-filling machines entered the food and beverage factories. At times vitamins and minerals are also added to drinks and edibles, usually in liquid form sealed in capsules. The capsule’s small size makes it much more convenient and user-friendly.

Every capsule contains the same amount of every solution of a specific liquid. Thus it also ensures that the exact amount of product is used by people to add to edibles and beverages. It is efficient, and the perfect amount of the desired product is always used.

Advantages Of Installing A Liquid Capsule Filling Machine In An Industry

Other than being extremely versatile, capsule-filling machines have several advantages. Even if there are any cons, they get highly outnumbered by the numerous pros of using this machinery.

Some of the most appreciated benefits are listed below:

The Machines Are Very Efficient

Every industry needs to reach production targets daily. With the help of these machines, they can handle the massive bulk of capsules being filled every day within just a few seconds. The high volume of capsule medicine production every day by these machines is very praiseworthy.

Its quickness and effectiveness aid firms in achieving production goals and cutting down on lead times, eventually leading to a more streamlined and effective manufacturing process.

Their Accuracy Never Fails

Most liquid capsule-filling machines are automatic and run by artificial intelligence to avoid mistakes that generally occur if the work is done manually. The machines have been specifically created to disperse accurate amounts of liquid (the information for the measurement of the liquid is assigned to the AI during the initiation) into the capsules.

Each capsule should contain the correct solution, which becomes more critical in medicine factories. The measurement of the drug being filled cannot go wrong. Everyone is aware of the adverse effects that can be caused to the patient’s body if the dosage of the drug goes even slightly wrong.

The Machines Are Extremely Cost-Effective

One of the most fundamental reasons why large-scale manufacturing companies and factories have implemented liquid capsule-filling machines in the production process is that they are very cost-effective. Being automatic cuts off the expense of manual labor and minimizes the propensity for human errors.

Being highly efficient, the machinery significantly reduces the amount of waste created and the tendency towards chemical hazards which were common when these jobs were done manually. Hence, the machine reduces cost as well as the overall risk factors.

Conclusion

According to various reviews, studies, and even surveys conducted over the years, it has been noticed that the use of liquid capsule-filling machines has taken a giant leap. Every person has put the advantages offered by this versatile mechanism into good use.

With new factories and companies popping up in every corner of the world, the production of capsule-based products is sure to increase, and so will the production and use of capsule-filling machines. They have proven to be very efficient and significantly pushed productivity. They rightfully deserve the popularity that they have gained.