If you’re reading this article now, we guess that you’re already thinking about making a purchase of an appropriate mini CNC router. You’re definitely not the only one who’s interested in its wide and handy application – nowadays, these little, super practical machines can be found almost everywhere. And, not only their use covers huge industrial establishments, but also home workrooms of all kinds. Basically, we could say that a manufacturing procedure that doesn’t include these simply doesn’t exist. Or it’s rather rare. And that’s what makes it even more special for artisans.

But, in order to be able to choose the piece of equipment that’s best for you and your needs, first of all, you’ll have some important questions answered. As you can imagine, today we can find many different series of products in the market and not all of them are convenient for every production circumstances. Also, it’s well-known that there’s a difference between classic CNC router, which has a wider range of use, and a mini one, which should be used for some “lighter” tasks.

How do I choose it and what should I consider?

It depends on various factors:

- Good research. Before you decide to buy anything, what you need is to perform thorough research and explore the best possible options for your purchase. First of all, the Internet is your friend. Google, more precisely. There are so many websites out there that might be a perfect helping hand if you’re rather confused and not sure where to start from and in case you need to decide if the mini version would be more appropriate for your business or a hobby. Also, if you simply want to see different models, compare prices or get informed about the key features – it’s possible to learn more here, as this website offers so much useful information about this and many other devices. The best part about web pages like these is that you get to find honest reviews of the people who have already purchased it. They sometimes even post pictures of their masterpieces in order to show the effect to potential buyers and convince them to invest in such equipment.

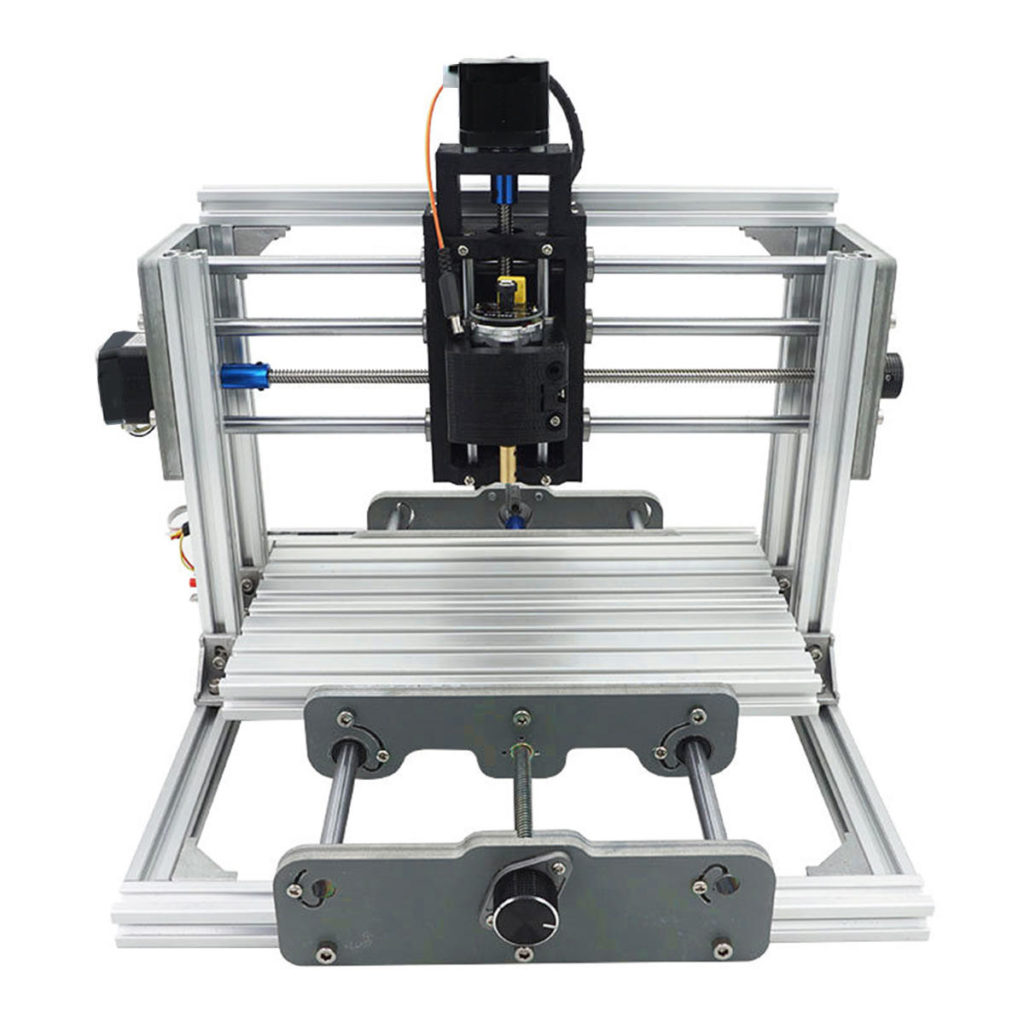

- Complexity of the process you want to perform. Mini CNC routers are more than convenient for performing tasks that include carving or engraving softer materials, like wood, PVC, plastic or softer kinds of metals. And, even if they’re able to help with challenging processes, not all of them will be appropriate for every kind of procedure. There’s one type for engraving and milling wood, and another for aluminium or some metals that are arduous for processing, like stainless steel. It’s fundamental to know that you won’t be able to treat all kinds of metals and materials equally well with such a small piece of equipment – this is mostly a resolution for home crafts, some less demanding manufacturing activities. You should definitely have it in your mind if you decided to purchase exactly this type of router.

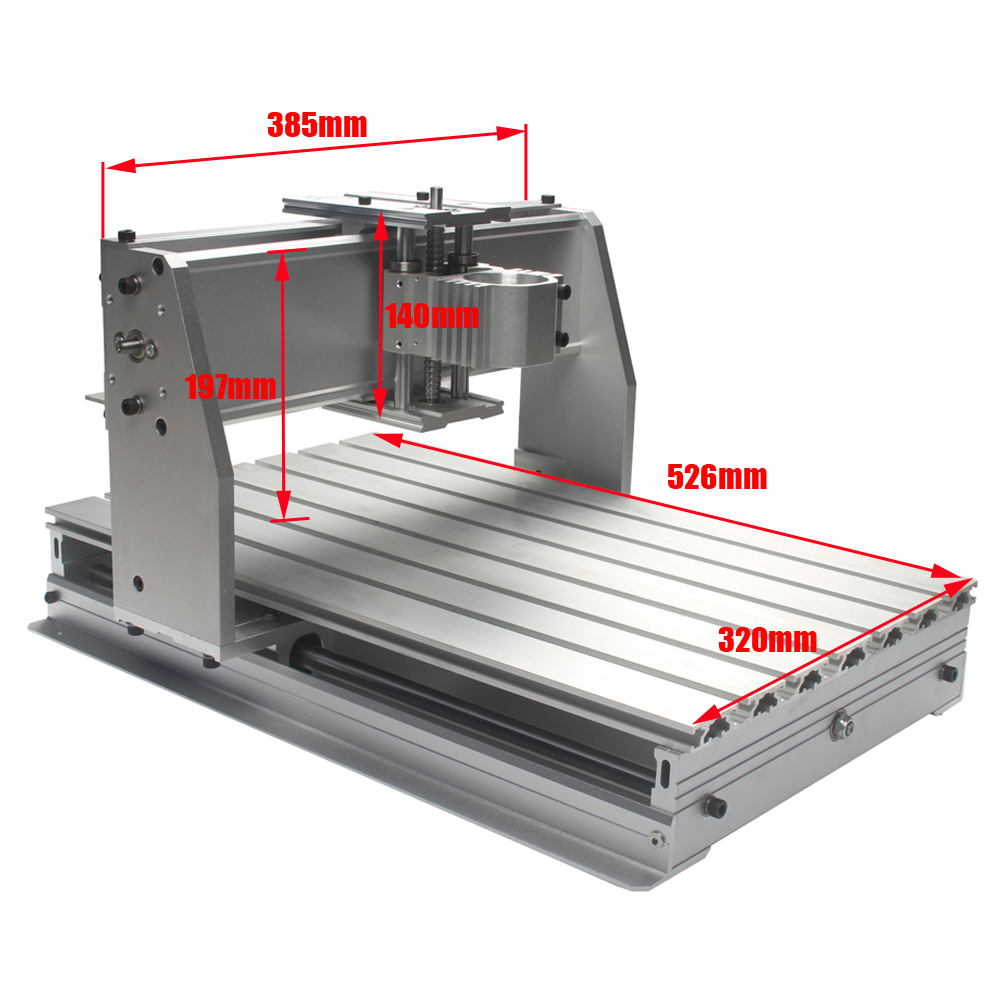

- Its working area and its size. Think wisely regarding this point. It could sometimes be a truly complicated thing to determine, so it’s quite a major concern to be able to decide what you will use the device for. If your needs exceed the size of this part of the machine, you’ll need to accept that you’ve just wasted a significant amount of money, without the possibility to rectify this. However, it’s not easy either if this area seems to be too big, as this will probably cost more, but you won’t be able to use its full potential.

- The size of the workspace. Another thing to consider is the size of the surface where the equipment would be placed. Mini CNC routers aren’t robust – they’re easy to fit in to any working table, however, just in case, you should definitely check if you need some more space for it in your workshop.

- The price. These criteria vary depending on the features of your mini router. If the machine’s able to perform more complex tasks, with different kinds of less or more demanding stuff and if it has a bigger working area, its price could easily increase. Also, if you’re aware of the fact that it would definitely need an upgrade for the needs of better performance, for example, to go from 3-axis to 4-axis configuration or introduce any other kind of upgrade.

- It’s a plus if it’s easy to assemble. Many times we’ve bumped into various reviews that stated that one of the biggest disadvantages of these products is that you need to assemble it yourself after the purchase. Therefore, this process might take some time, some nerves and also a bunch of effort, especially when you’re not sure how to do it right or if the manual isn’t clear enough.

- The place from which you’ll buy your machine. Although internet sale has its own advantages and benefits, it’s preferable to leave it for some other things, like tiny additional device parts, nuts or anything similar that already has determined size. One definitely shouldn’t gamble with the purchase of this type, as it’s simply necessary to see the machine with your own eyes, in real time, to observe all necessary parameters and then decide. Of course, the best resolution would be relying on renowned producers and manufacturers that can guarantee the quality of their machines. Sometimes you might pay more, but the outcome will be perfect – it’s your own decision.

- Warranty from the manufacturer. This is a must, especially if you put aside a significant amount of money to buy your own baby. No device is perfect – it’s always possible for various issues to happen and spoil the working capacity of the machine. While it doesn’t necessarily mean that you’ll need a new one right away, it’s always good to have a warranty and be sure that the problem could easily be resolved in the speed of the light with the help of the technical and customer support.