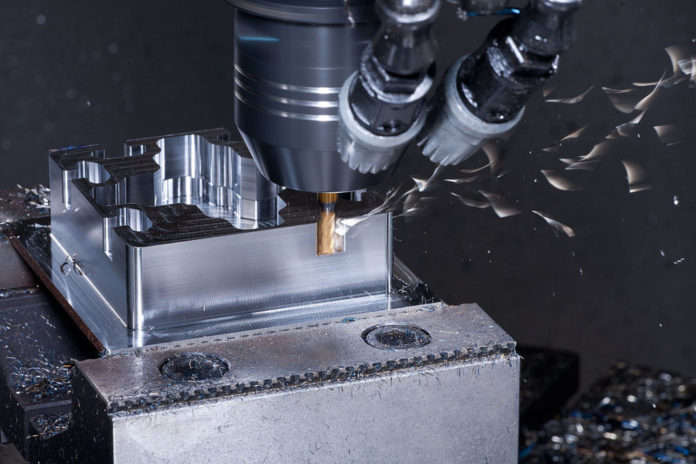

A CNC machine can be described as an electro-mechanical device, used to operate with tools via programmed computer inputs. The name “CNC” stands short for “Computer Numerical Control“.

I think it’s safe to say that these machines completely re-invented the way in which we manufacture things.

CNC machines were first invented in the early 1940s and they depended on a common telecommunication data storage technology that is also known as “punched tape”. This technology soon became “out of date” because the data medium pretty soon transitioned into analog, and later in digital computer processing. This happened in the late 1950s.

There are two types of CNC machines and they can often be categorized as conventional and novel machining technology.

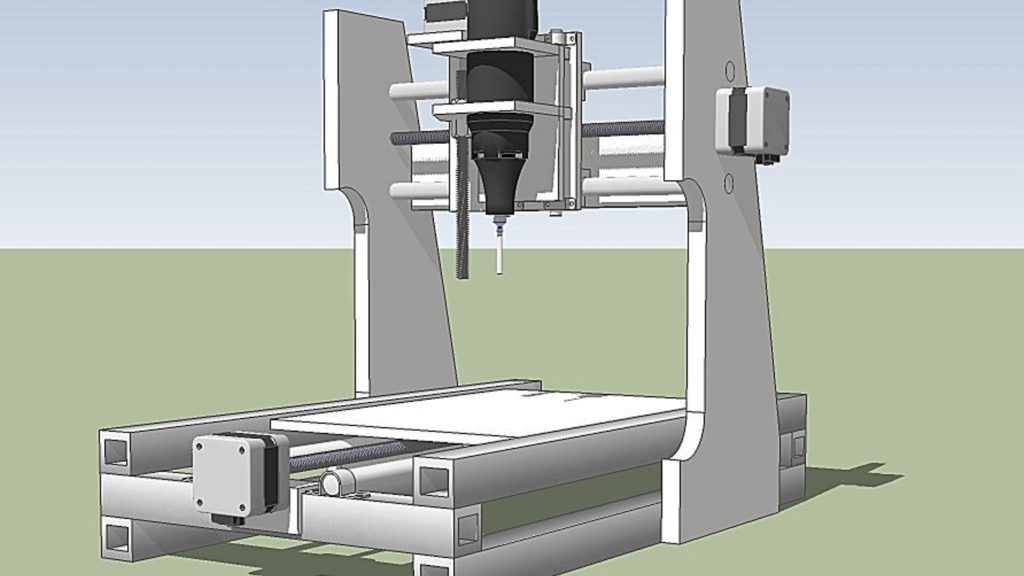

So, now that we learned a little about CNC machines, let’s see if we can make our own at home.

There are some questions that you need to answer before deciding what kind of a CNC machine you want to start building.

How much will it cost us?

Some CNC machines can be more expensive than others and they might require more parts that might be difficult to acquire. If your local hardware stores don’t have some of the necessary parts needed for your build, you might have to visit some websites specialized in this, like ArtMachining for example.

How difficult will it be?

Again, some CNC machines might be more difficult to build than others. You need to weigh the pros and cons of the time you will spend building one and the possibility for failure, versus buying one instead.

What kind of projects are you going to work on?

What are you willing to create using your new CNC machine? If you can answer this question, it will greatly affect your decision on what type of a CNC machine to build, as well as the specified parts that you need to acquire before you start building it.

What you will probably need to start building your own CNC machine:

As we already mentioned above, there are many different types of CNC machines and a lot of different options and possibilities. However, the parts that we will list below for you, are probably included in almost every type of a CNC machine. So without further ado, let’s see what you need to start your first build.

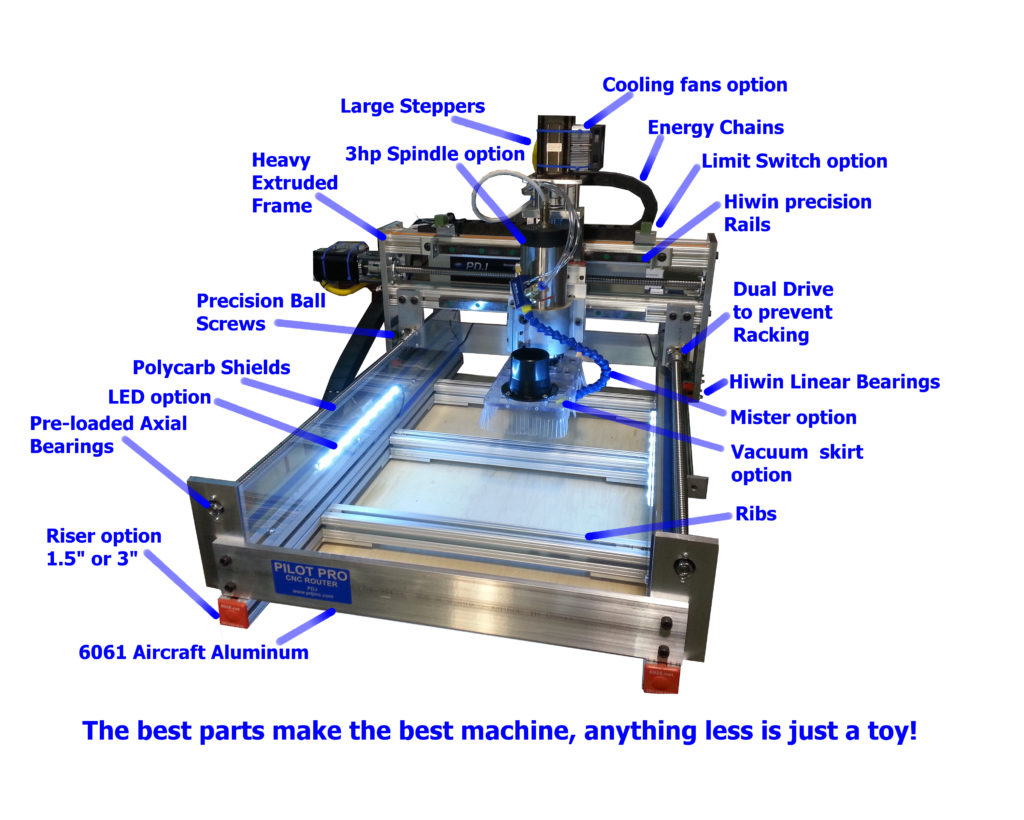

The electrical parts

- A power supply (The main power source for the CNC machine)

- Some motors (What’s going to move the parts)

- Stepper drivers and a stepper shield

- A control board / a processor (some CNC machines might be able to use a personal computer)

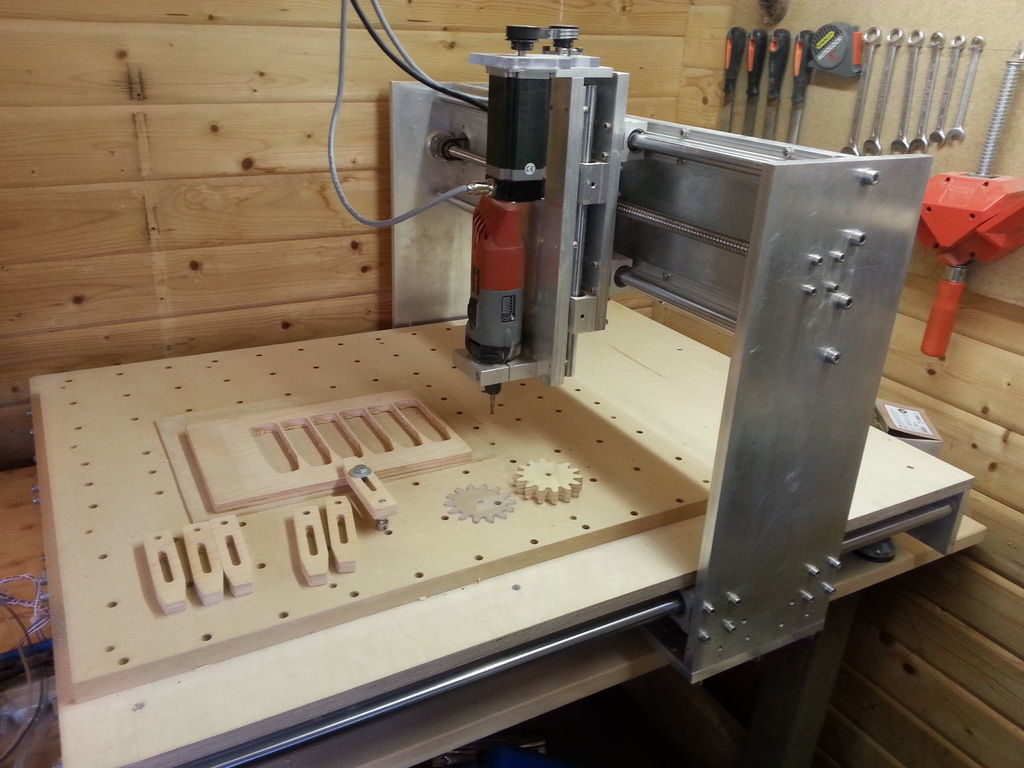

The mechanical parts

- Screws, bolts, spacers, and washers (Required for putting parts together)

- Bearings

- Frames

- Cutting tools (What the CNC machine is going to operate with)

Img source: pdjinc.com

Again, as mentioned above, if you decide exactly which type of a CNC machine you’re going to build, it will be much easier to narrow down the parts that you will need for your build.

Now that you’ve read our article about building a CNC machine, you’re probably thinking about starting your own build. If you’re still hesitating on whether or not you should build one, we wrote a quick summary for you with all the benefits that you get if you make your own CNC machine.

Fully customizable

If you buy a CNC machine from a store, it may or may not include some of the features that you want or do not want to be included. However, if you build one yourself, you can decide which features to build in it and which ones to exclude. You can’t go wrong with this.

Saving your money

CNC machines are great and very helpful, but, they sometimes can cost thousands of dollars and not everyone can afford to buy a brand new one from a store. If you decide to build one yourself, you will save this crazy amount of money that you would normally use to get one from the store.

Creating amazing products

Well, this feature really applies to every CNC machine, doesn’t matter whether you bought one or built one yourself, but it’s true anyway. Having a CNC machine in your tool arsenal will help you create amazing products. You can start your own business or maybe create some parts that are otherwise hard to find in your area, a huge number of possibilities, really.

Get it done with a CNC machine. And in case you don’t have the time or the money to create one for yourself, check out artmachining.com for their services.