Printed circuit boards or PCBs can be manufactured from a wide range of metals. Generally speaking, these specific items are commonly referred to as metal-core components. The metal that can be utilized for producing these components will depend on what they’ll be used for, and of course, what applications they’ll have in the future.

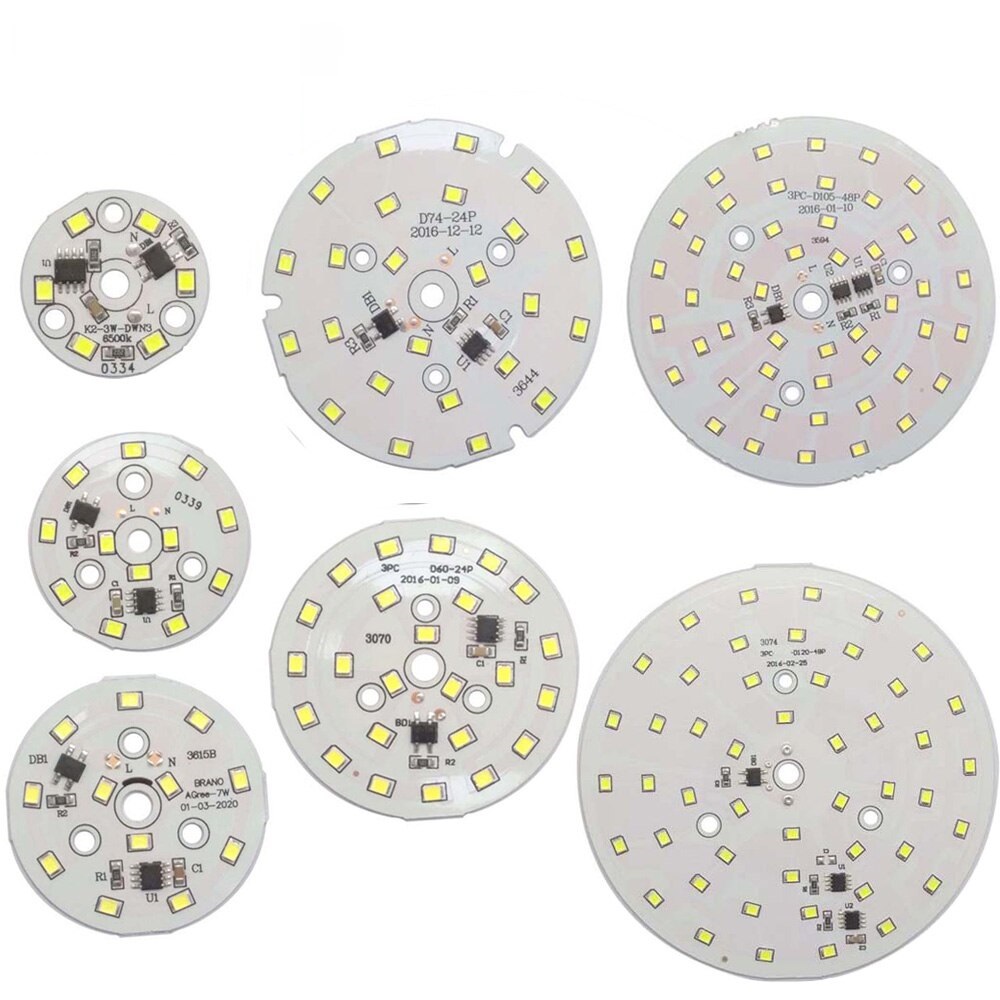

The ones created from aluminum are usually utilized the most and applied to various industries today. The devices are usually metal-based and the copper-clad coating offers them great thermic conduction and electrical protector. If you want to learn more about these important electrical parts, the text below might be quite useful for you. Especially since it will feature 6 things that you should know about these components created from aluminum. Let’s take a closer look at the list:

1. The Backstory

PCBs are closely related to the electrical links that were shown to the public more than a century ago. These links included metal pieces and rods connected to huge electrical parts that were joined with wooden bases. However, as time passed manufacturers started using cables that were joined with screw platforms, hence, they completely replaced the metal pieces.

Although the improvements mentioned above were quite significant, the devices were extremely big and they were not able to meet the increased demand for tinier devices and smaller printed circuit boards. Since the need continued rising, Charles Ducas from America designed a stencil. This design included conductive links that could let’s say, “print” the electronic routes on the board.

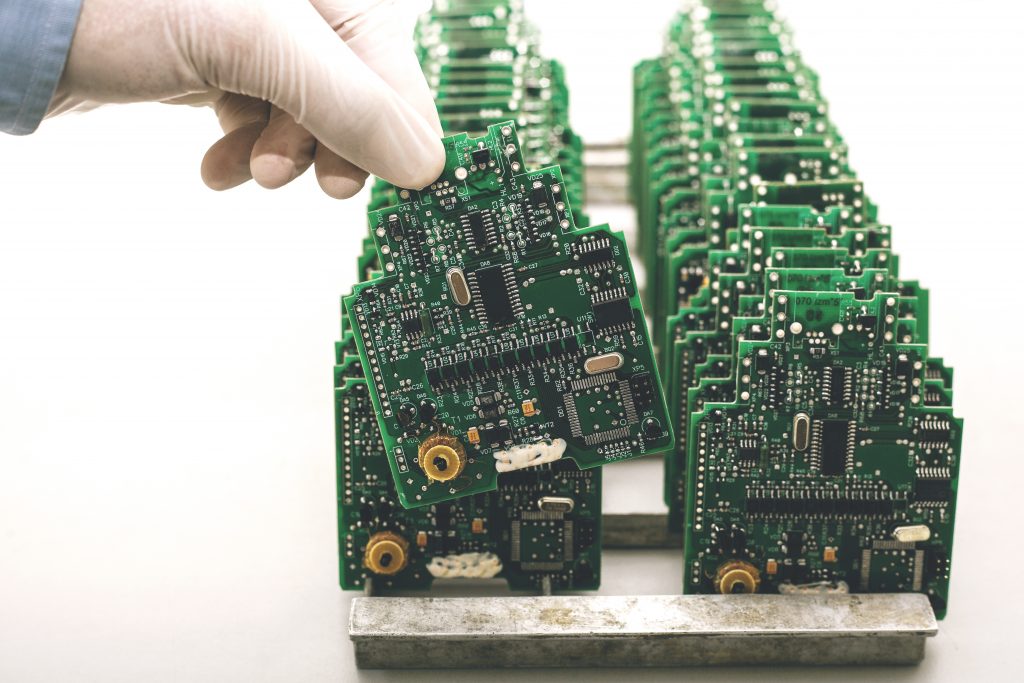

The ‘70s witnessed superior use of these components when compared to the previous years, and in the last decade or so, there was an increase in the demand and use of these devices – which mainly happened because of all the advancements in the LED field. Nowadays, various electronic parts manufacturers depend on these PCBs, especially since they offer a wide range of benefits.

2. The Advantages of Using PCBs

When you compare this type with other ones, there is a pretty good reason people choose to use them, more specifically, for producing electrical parts all over the world. For starters, these devices are less costly because aluminum is a relatively inexpensive substance. Furthermore, it is easy to excavate and purify this material, hence, various manufacturers can lower their expenses.

They are also environmentally friendly, which is something that is incredibly important for a lot of people today. Additionally, it is also recyclable and non-poisonous. The boards also have amazing heat transfer and radiation, hence, it is able to sustain extremely great warmth. They are quite tough and lightweight, indicating that they won’t add weight to the device they are used in.

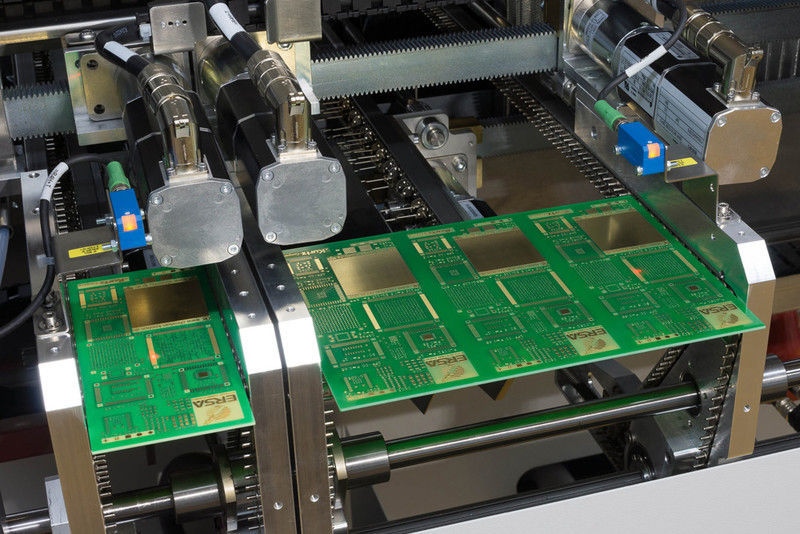

3. The Production Process

The chief differences between aluminum and other board types are in the production method – especially the chemical milling step. During production, a frail sheet of a dielectric is attached to both the circuit and the foundation coat. This coat can conduct temperature and it can also provide electric insulation.

After that is attached, the copper sheet needs to be etched and this is the step that actually creates the desired design. The metal strip and the light dielectric coat aids with removing excess warmth from the circuit. Besides being specific, creating these electrical components it is perhaps, one of the most difficult processes in this enterprise. If you want to see more information about these PCBs, you can visit www.pcbonline.com.

4. The 3 Varieties

There are 3 main models that you can choose from, including:

– Through-hole – during the production, the aluminum is pierced and stuffed with a dielectric substance. After that, the aluminum needs to be laminated which is the stage where specific thermic bonding tools need to be used. Following this stage, the aluminum PCB needs to be through-drilled.

– Flexible – nowadays, these adaptable strips are standard in the electronic industry and it is often referred to as one of the newest advancements in the insulated metal substrates materials. There is a big demand for this type because it provides perfect cushioning, adaptability, and conductivity.

– Hybrid – this type is made by a method that uses energy to join the non-thermal parts on the aluminum substrate. In most situations, the implementation of 2 or 4 layers. Now, these are used less often, however, they are quintessential parts of some crucial appliances.

5. The Different Uses

Devices that need high-power or heat to work rely heavily on these components. Although the idea behind these components was to change the supply parts that need high power, they have gain popularity instantly, and today, they are most frequently utilized in the LED industry for items such as illumination, traffic lights, as well as lighting for vehicles.

Other fields where these components are utilized include energy supplies, high-current, engine controllers, the automotive industry, as well as signal beacons, scanners, surgical lamps, tail lights, and vehicle technology. PCBs are highly demanded because they are more efficient, reliable, and effective than, for instance, ones manufactured from fiberglass.

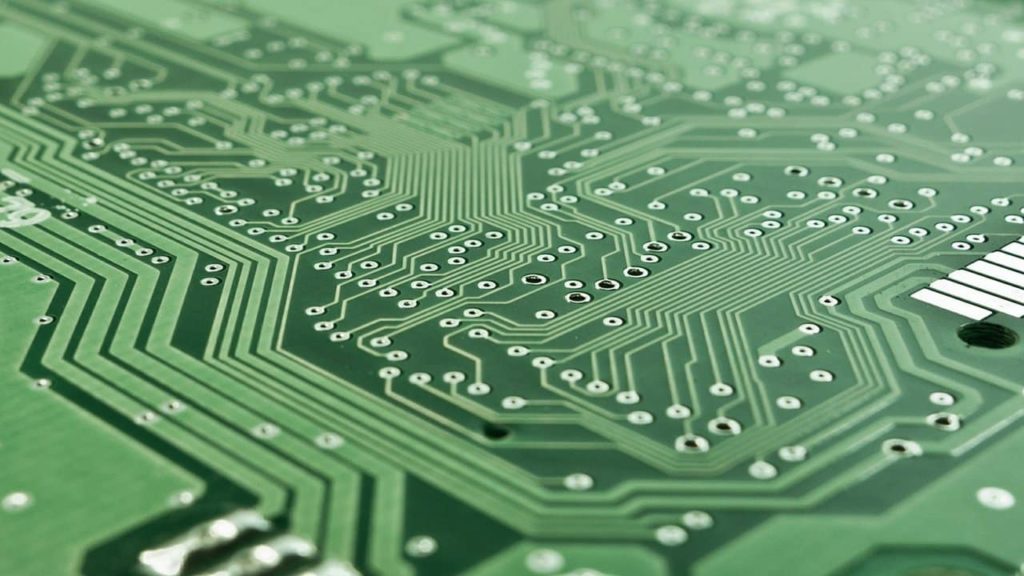

6. It Has 3 Layers

As previously mentioned, this type is produced and designed uniquely, hence, there are 3 principal layers including:

– The Circuit Surface – this base is mainly produced by utilizing copper foil. This material weighs from 28 to 283 grams, however, in some cases, there might be heavier.

– The Thermal Surface – this part is created from a ceramic polymer. Besides being incredibly heat-resistant, it is also long-lasting and elastic which adds more reliability to the part. It aids in protecting the PCB from mechanical, heat, and additional detrimental things.

– The Base Surface – this coat is manufactured from an aluminum composite substrate. And they are perfect for the aforementioned through-hole type, especially because there is aluminum in it.

Conclusion

As you can see, the backstory and facts about aluminum printed circuit boards are quite interesting. They offer a wide range of benefits in various industries, and besides being cost-efficient, they are also more efficient and reliable than other PCB types. So, now that you know these six things about PCBs, do not waste any more time. Instead, start searching for a company that will be able to help you with manufacturing the aluminum PCB that can fit your project needs and requirements.