We live in a world that technology is going forward in every aspect of life. We use many different materials to create different things all in order to make our lives easier. One of the most commonly used materials to create new products is plastic. The reason why we are using plastic and its polymers are because they are really durable, some of the polymers are really easy to bend without breaking and cracking and they can resist high pressure, temperatures, and different acids and detergents.

There are many manufacturers that create these products and if you do research, you will realize that injection molding products are the most common ones on the market. There are so many things that are created by the injection molding process and we use them every day.

Here we are going to talk about those products and the use we have in our everyday lives. You should know that there are usually different types of plastic to choose from and the manufacturers choose the best polymer for the product needed. The price and durability can vary depending on the material and the manufacturing time takes usually a few hours to a few days, depending on the product.

Types of plastic

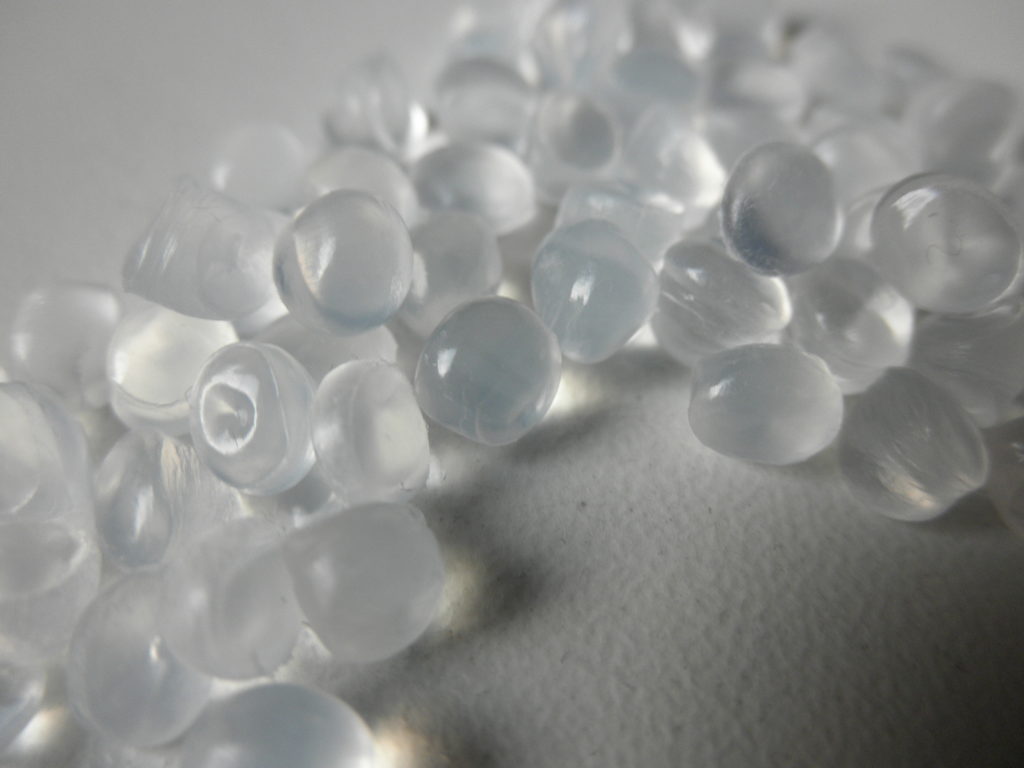

Let’s first start with the types of plastic that manufacturers use when creating injection molding products. There are different products and they are used for different things and different moldings. Now we are going to look at the most commonly used ones and how you can use them to your advantage.

Polycarbonate

It is used to create things that will be resistant to wear and tear. This plastic is commonly used to create phones, medical devices, and car components. However, since you won’t be making your own car anytime soon, you can use a PC in your greenhouse and backyard.

This plastic will survive the test of time and you won’t need to replace anything anytime soon.

Polyethylene

Probably one of the most versatile products, this polymer has wide use in so many aspects of everyday life. It’s been around for more than a few decades and nowadays it is used for plastic bottles, bags, films and so on.

Polyethylene does not absorb moisture; it is a strong polymer and it is recyclable.

Polypropylene

This is probably the most used plastics of all for molding. It has resistance to cracking, it does not break when it comes in contact with detergents and water, and it also has great impact strength.

It is also used as a food container because it is safe to use in the household.

Injection molding products

There are a lot of products that can be made by injection molding. Here we are going to talk about the most common uses of injection molding and the applications. There are also many different processes that manufacturers use to create these products. Overmolding, insert molding and CNC machining are some of the most common ones, and you can check this if you want to learn more about the manufacturing processes.

1. Toys

This is one of the most common use. Why? Well, because with this type of molding manufacturers are able to create products that are safe, durable and can come in a variety of different colors, shapes, and sizes.

One of the most famous brands that use this type of molding is Lego. They make their building blocks by heating the plastic and injecting it into metal molds. When the plastic is cooled down and solidified, it gets the famous look. Each brick must be accurately molded so that they all fit together.

2. Bottles

The plastic bottles are something that has been produced for decades now. They have a variety of uses, starting from holding water up to other beverages and fluids.

They are made in different shapes and sizes and they are really durable. Plastic bottles can withstand huge temperature differences and most of them won’t break or get damaged with time.

3. Household items

When it comes to householding and the items that are made by injection molding, there is a variety of products that are made.

The most common product manufactured by this process is the drinkware, and other things include food and other types of containers, closures, and components.

4. Electronic housing

Did you know that your remote controls, TVs, and computers are actually manufactured with this type of process? And not only that, the injection molding process is used to manufacture housings and electronic components.

The great thing about the process is that it can turn plastic to any component no matter the size, shape or the application that it should be used for.

5. Agricultural

As technology gets more advanced, many manufacturers realized that plastic components are better and cheaper than metal ones.

That happens because most polymers resist extreme temperatures, they don’t break during use and are resistant to humidity. The additives protect the polymers from corrosive substances and harsh weather. Nowadays, most agricultural components are made by injection molding.

6. Healthcare

As you already know, in healthcare there are many products that need to be reused and also, there are many who get thrown away after one use only. Because of that, the products need to be made in bulk, they need to be safe for use and they also need to be durable.

In order to get everything sanitized and safe for the patients, plastic is used because it can withstand high temperatures and it is resistant to acid and disinfectants.

Most of the products, like syringes, are made by injection molding and this process helps doctors and nurses get the job done while everything is safe and sterile.

Here is a list of some of the things that are manufactured with plastic injection molding:

- Electrical Boxes

- Medication Trays

- Insulators

- Skateboard Storage Racks

- Toilet Seats

- Children’s Furniture

- Flower Pots

- Exercise Tools

As you can already notice, this type of manufacturing is used for most everyday items. If you want to know more about the whole process and how it is all done, you can consult a professional or even ask to see if there are open days when you can visit the companies that produce these products.